When you want to know what is petg, you should know it is a glycol-modified version of PET. This material is popular for 3D printing. It stands out because it is clear, strong, and does not break easily. In modern manufacturing, what is petg is important. Its mechanical properties, like tensile and compressive strengths, can be changed and trusted. You will find what is petg helpful if you want low warping and easy use. PETG works well in 3D printing, making things, and food-safe uses.

Key Takeaways

- PETG is a tough, see-through plastic used in 3D printing, packaging, and medical tools. It bends easily and does not snap. It handles heat, chemicals, and hits better than PLA and ABS. PETG is simple to print with. It does not warp much and sticks well to the print bed. This makes it good for both new and skilled users. Set the nozzle between 230°C and 250°C. Use a heated bed at 70°C for best 3D prints.

Keep PETG filament dry. Clean your printer nozzle to stop problems like stringing and oozing. PETG is safe for food and medical items. The FDA says it is okay for these uses. Make parts with thick walls and round edges. This stops them from breaking and makes them last longer. PETG can be recycled. But you must sort and clean it well for better recycling.

What is PETG

Chemical Structure

You might wonder how PETG is not like other plastics. PETG means polyethylene terephthalate glycol. It is a kind of thermoplastic polymer resin. To make PETG, manufacturers add glycol to PET when making it. This change with glycol makes the molecules different. It adds carboxyl and hydroxyl groups to the chains. These changes make the molecules heavier and give PETG special traits.

PETG is an amorphous copolyester. It forms when ethylene glycol, cyclohexanedimethanol, and terephthalic acid mix together. The glycol part helps PETG bend without breaking and fight chemicals. PETG does not turn solid like regular PET. This makes it simple to use and gives it a clear look like glass.

Key Features

When you check what is petg, you find many good things. PETG is strong, bends well, and looks clear. It is tough and does not break from hits. You can print with PETG and see little warping or shrinking. This keeps your 3D prints the right shape.

Here is a table that shows how PETG compares to other 3D printing plastics:

| Property | PETG | PLA | ABS |

|---|---|---|---|

| Impact Resistance | High, ideal for functional parts | Moderate, more brittle | High, but can crack |

| Warping | Low, minimal shrinkage | Very low | High, needs careful control |

PETG has a glass transition temperature of about 70–85°C. This helps it handle heat better than PLA. Its chemical makeup lets it mix with many additives. You can get PETG blends for special needs.

PETG is easy to print. It sticks to the print bed and does not need a cover. Its clear look makes it great for see-through parts and boxes. PETG is also safe for food in many cases.

Why It Matters

You may ask why PETG is important for making things and 3D printing. The answer is its mix of good traits and how easy it is to use. PETG is strong, with tensile strength between 41.5 and 44.5 MPa and impact strength of 5–6 KJ/m². It can stretch before it breaks, with elongation at break around 10–12%. These things make PETG a top pick for strong, useful parts.

You can use PETG in many fields. More people use it because it works for both hobbyists and pros. Here are some reasons PETG is special:

- PETG has better impact resistance, lasts longer, and handles heat better than PLA and ABS.

- More 3D printing in planes, cars, health, and goods means more PETG is needed.

- PETG is simple to use and fits many 3D printers.

- New PETG blends, like heat-resistant or bio-based types, give more choices.

PETG’s chemical resistance and safety for the body make it good for medical tools and food boxes. You can trust PETG for parts that must last and stay strong. Its low warping and good sticking help you get great prints every time.

PETG Properties

Strength

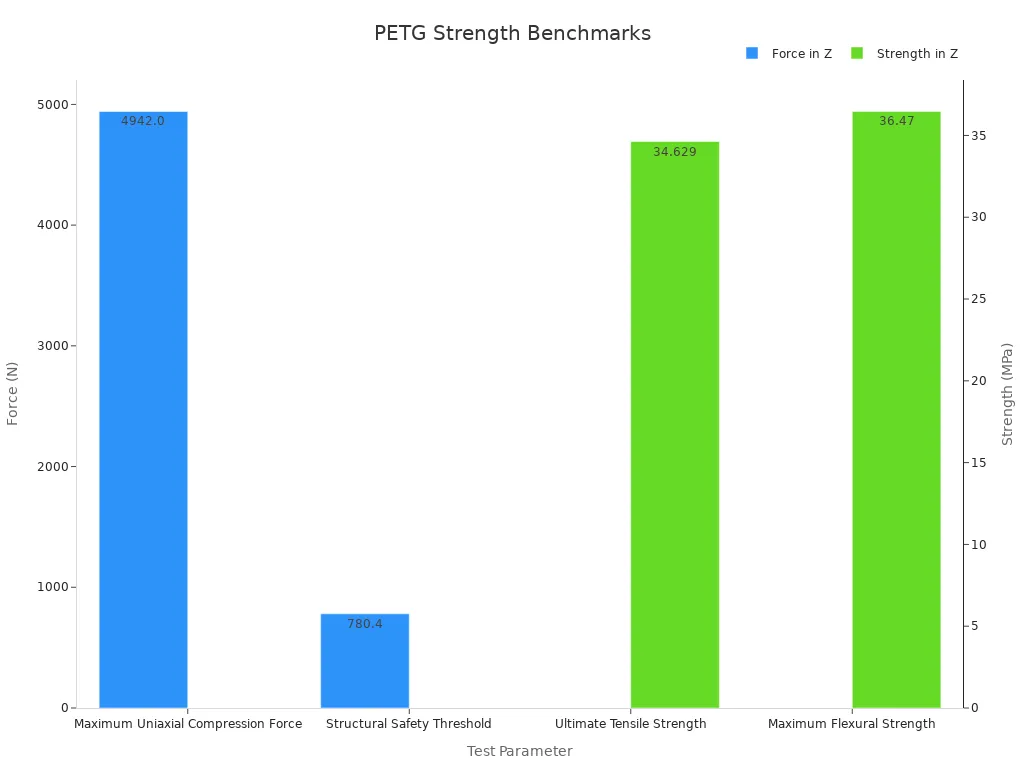

When you look at PETG, you see a plastic with impressive strength. This material can handle high forces before it breaks or bends. You can use PETG for parts that need to stay strong under pressure. Many tests show how PETG stands out compared to other plastics. For example, PETG can handle a maximum uniaxial compression force of 4942.0 N in the Z direction. This is much higher than the minimum safety requirement of 780.4 N. The ultimate tensile strength reaches 34.629 MPa, and the maximum flexural strength is 36.47 MPa. These numbers prove that PETG is a reliable choice for strong parts.

| Test Parameter | Value (Z Direction) | Value (X–Y Direction) | Standard/Requirement Reference |

|---|---|---|---|

| Maximum Uniaxial Compression Force | 4942.0 N | 2930.0 N | Spanish CTE standard requires 780.4 N |

| Ultimate Tensile Strength | 34.629 MPa | N/A | ISO-604 standard |

| Maximum Flexural Strength | 36.47 MPa | N/A | N/A |

| Structural Safety Threshold | 780.4 N | N/A | Spanish CTE standard |

You can also see the results in this chart, which shows how PETG performs in different strength tests:

These benchmarks show that PETG is not just strong, but also meets and exceeds many safety standards. You can trust this plastic for projects that need high strength.

Durability

PETG is known for its durability. You can use it in tough environments, and it will last a long time. Studies show that PETG keeps its mechanical properties even when exposed to harsh conditions. For example, researchers tested PETG in seawater at high temperatures. The material absorbed less than 1% water, which means it does not swell or weaken easily. Even after long exposure, PETG kept its shape and strength.

Scientists used special tests, like ANOVA and Tukey tests, to check how PETG performs over time. These tests showed that PETG stays stable and does not lose its strength quickly. You can rely on PETG for parts that need to work in water, heat, or other tough places. This makes PETG a good choice for outdoor or industrial uses.

Chemical Resistance

PETG stands out for its chemical resistance. You can use this plastic with many chemicals, and it will not break down or lose its properties. PETG is a thermoplastic polyester with glycol added, which improves its chemical properties. This means PETG can resist water, acids, and many cleaning agents. It does not absorb much water, so it stays strong and clear even in wet conditions.

You can use PETG for food containers, medical parts, and other items that need to be safe and clean. The FDA approves PETG for food contact, so you know it is non-toxic and safe. PETG’s chemical resistance makes it a smart choice for many applications where other plastics might fail.

Clarity

You will notice that PETG stands out for its excellent clarity. This material looks almost as clear as glass. When you print with PETG, you can create parts that let light pass through easily. Many people choose PETG for projects where you want to see inside or show off the inner parts. For example, you might use PETG to make display cases, protective covers, or light fixtures.

PETG keeps its clarity even after you shape or print it. You do not have to worry about the material turning yellow or cloudy over time. This makes PETG a great choice for products that need to look clean and professional. If you want to add color, PETG also takes dyes well. You can find PETG in many bright and clear colors.

Tip: If you want the clearest results, use the right print settings and keep your printer clean. Dust or dirt can affect the final look of your PETG prints.

Flexibility

PETG gives you a good balance between strength and flexibility. You can bend or twist this material without it snapping or breaking. This makes PETG useful for parts that need to move or flex, such as clips, hinges, or snap-fit joints. You will find that PETG can handle repeated bending much better than some other plastics.

Experiments show that PETG keeps its flexibility across different temperatures. You can bend or twist PETG parts even when they are warm or cool. PETG does not lose its shape or become brittle easily. If you need even more flexibility, you can anneal PETG by heating it at 70-80°C for a few hours. This process helps the material become even tougher and more flexible.

Here is a quick look at how PETG compares to other common 3D printing plastics:

| Property | PETG | PLA | ABS |

|---|---|---|---|

| Flexibility | High | Low | Medium |

| Snap-fit Parts | Yes | No | Yes |

| Bending Without Breaking | Yes | No | Sometimes |

Heat Resistance

PETG handles heat better than many other 3D printing materials. You can use PETG for parts that need to stay strong in warm places. PETG has a glass transition temperature between 70°C and 85°C. This means it keeps its shape and strength up to these temperatures.

Standard tests show that PETG keeps its bending strength even when you print it at different nozzle temperatures, from 235°C to 265°C. The material does not lose its toughness or become weak. PETG also has a stable thermal conductivity, which means it can handle changes in temperature without problems.

- PETG works well at printing temperatures above 230°C.

- The material keeps its mechanical properties even when you change the printing temperature.

- PETG blends, like those with carbon fiber, can handle heat even better.

You can trust PETG for projects that need to resist heat, such as machine parts, outdoor signs, or kitchen tools. PETG gives you a strong and reliable option when you need both heat resistance and durability.

PETG vs Other Plastics

When you pick a plastic, you might wonder how PETG is different from others. PETG is special because it is strong, bends well, and looks clear. You can see how PETG is not the same as PET, PLA, or ABS.

PETG vs PET

PETG and PET look alike, but they are not the same. PETG is made by adding cyclohexanedimethanol (CHDM) to PET. This makes PETG better at handling hits and chemicals. PETG melts at a lower temperature, between 180°C and 200°C. This makes it easier to use for 3D printing and molding.

| Property / Aspect | PET | PETG |

|---|---|---|

| Chemical Composition | Crystalline polymer | Glycol-modified copolyester |

| Melting Point | ~250°C | 180°C-200°C |

| Impact Resistance | Good | Superior |

| Flexibility | Moderate | High |

| Transparency | Good | Excellent |

| Applications | Bottles, textiles, electronics | Medical devices, 3D printing, packaging |

| Recycling | Widely recycled | Less developed recycling |

You will see PETG in medical tools, clear packages, and as a greener choice than PVC. PET is used for bottles and clothes. PETG is tougher and bends more, so it is better for parts that need to last and stay clear.

Note: PETG melts at a lower temperature, so it is easier to print or mold than PET.

PETG vs PLA

If you use 3D printers, you may compare PETG and PLA. PLA is simple to print and good for easy models. PETG is stronger and bends more. It also handles heat and chemicals better than PLA.

| Property | PETG | PLA |

|---|---|---|

| Tensile Strength | 55-60 MPa | 40-60 MPa |

| Impact Resistance | High | Low |

| Heat Resistance | Up to 80°C | Around 60°C |

| UV Resistance | High | Low |

| Flexibility | More flexible | More rigid |

| Chemical Resistance | Better | Lower |

| Ease of Printing | Moderate | Easy |

PETG is good for parts that need to bend or take a hit. PLA is best for things that do not need to be strong. PETG can handle sunlight and chemicals, so you can use it outside or for food-safe things.

Tip: PETG sticks together better, so your prints are stronger and last longer.

PETG vs ABS

You might want to know how PETG and ABS are different. ABS is tough and used in toys like LEGO bricks. PETG is strong too, but it is easier to print and does not warp as much.

- PETG prints at lower temperatures than ABS.

- PETG warps and cracks less than ABS.

- PETG is clear and shiny, but ABS is not see-through.

- PETG is often safe for food, but ABS is not.

PETG is strong, bends well, and is clear. It works for many projects that need to last, look good, and be easy to make.

3D Printing Material

3D Printing with PETG

You will find PETG is a favorite choice for 3d printing. This 3d printing material works well with fused deposition modeling, which is the most common type of desktop 3d printing. PETG combines strength, clarity, and flexibility, making it ideal for both beginners and experts. You can use PETG to create parts that need to be tough and clear, such as protective covers, mechanical parts, or display cases. PETG resists warping, so your prints keep their shape. You can also use it for food-safe projects, as PETG is often approved for contact with food.

Print Settings

Getting the best results with PETG depends on using the right print settings. You can adjust several parameters to improve your 3d printing experience.

Temperature

You should set your nozzle temperature between 230°C and 250°C for PETG. This range helps the filament melt smoothly and stick to each layer. A heated bed at 70°C works well to keep the print attached and prevent warping. If you use these temperatures, you will see fewer problems with layer separation or weak prints.

Bed Adhesion

PETG sticks well to many surfaces. You can use a glass bed, PEI sheet, or painter’s tape. For extra grip, apply a thin layer of glue stick or hairspray. Good bed adhesion keeps your print from moving or lifting at the corners. You should also keep your print bed clean and level for the best results.

Here is a table showing optimal PETG print settings based on controlled experiments:

| Parameter | Tested Values | Optimal Value | Effects on Print Quality |

|---|---|---|---|

| Layer Height | 0.1 mm, 0.2 mm, 0.3 mm | 0.2 mm | Best balance of strength and clarity; fills gaps for smooth, clear prints |

| Extrusion Rate | 100%, 110%, 120% | 110% | Fills bonding gaps, improves strength and light transmittance |

| Printing Speed | 20 mm/s, 30 mm/s, 40 mm/s | 40 mm/s | Reduces bubbles, improves structure, and gives the clearest, strongest prints |

Common Issues

When you use PETG for 3d printing, you may notice some common issues. PETG absorbs moisture from the air, which can cause stringing and reduce print quality. You can dry your filament in a dehydrator at 65°C for about 8 hours to fix this. If you see strings or blobs, check your retraction settings and keep your filament dry.

PETG can flex under pressure. For example, printed tools like spanners may slip if you apply too much torque. In tests, an open-ended PETG spanner slipped at 0.6 Nm, while a closed-ended one slipped at 4.5 Nm. PETG also starts to deform at 100°C, so avoid using it for parts that face high heat.

Cracks may appear in your prints if you use the wrong orientation or strain the part too much. The way you print and the speed you use can affect how strong your PETG parts are. You can reduce these problems by following the recommended print settings and keeping your filament dry.

Tip: Store your PETG filament in a sealed bag with desiccant to keep it dry and ready for your next 3d printing project.

Uses

3D Printing

You will find PETG is one of the most popular materials for 3d printing. Many people choose it because it is strong, clear, and easy to use. When you use PETG for 3d printing, you can make parts that need to last a long time. You can also print objects that need to bend or take a hit without breaking. PETG works well for both beginners and experts in 3d printing.

Researchers have tested PETG in 3d printing by changing settings like speed, layer height, and infill. They found that PETG can reach high levels of strength and toughness. These tests used special models and experiments to check how PETG performs. You can trust PETG to give you good results if you want strong and reliable 3d printing parts. Many 3d printing applications use PETG for making tools, machine parts, and even dental models.

You can also use PETG for 3d printing dental aligners and other dental items. Dental labs often pick PETG because it is safe and clear. You will see PETG in many dental applications, such as retainers and mouth guards. PETG is also used for making medical equipment with 3d printing. You can print face shields, mask parts, and other protective gear.

Tip: If you want the best results with PETG in 3d printing, try different print settings to match your project needs.

Food Packaging

PETG is a top choice for food packaging. You can use it to make clear containers, bottles, and trays. PETG is safe for food contact and does not release harmful chemicals. It also keeps your food fresh and protected.

Here is a table that shows how PETG compares to PLA, another common plastic, for food packaging:

| Property | PLA Range | PETG Range |

|---|---|---|

| Impact Strength (kJ/m²) | 2 - 3 | 5 - 7 |

| Tensile Strength (MPa) | 40 - 60 | 50 - 75 |

| Heat Deflection Temp (°C) | 52 - 60 | 70 - 78 |

| Water Absorption (%) | 0.5 - 0.8 | 0.1 - 0.3 |

You can see that PETG is stronger, handles heat better, and absorbs less water than PLA. These features make PETG a better choice for food packaging that needs to last. PETG is also non-toxic, so you can use it for food storage without worry.

Medical

You will find PETG in many medical applications. Hospitals and clinics use PETG for making medical equipment, dental tools, and protective gear. PETG is popular in the dental field. You can see it used for dental aligners, retainers, and mouth guards. Dental labs like PETG because it is clear, strong, and safe for the mouth.

Researchers have studied PETG for medical uses. They tested how cells stick to PETG and how it holds up in tough conditions. Here is a table that shows some results from these studies:

| Aspect Evaluated | Description |

|---|---|

| Study Type | In-vitro experiments on rat bone marrow and peritoneal lavage cell adhesion to 3D-printed PETG |

| Cell Adhesion Results | Variable adhesion observed; no clear link with printing settings |

| Biodegradation Assessment | Mass changes in PETG samples varied, possibly due to chemical structure and additives |

| Comparison with Other Polymers | PLA showed more adhesion with bigger nozzle; PEEK did better with finer prints |

| Conclusion | PETG shows promise for biocompatibility but needs more clinical testing |

You can use PETG for dental and medical equipment because it is safe and strong. PETG is also used for 3d printing custom dental parts. Many dental clinics trust PETG for its clear look and reliable performance.

Industrial

You can find PETG in many factories and industries. It is strong, clear, and bends without breaking. Companies use PETG to make products that last and look nice. You will see PETG in packaging, signs, medical tools, and test models. These uses show PETG is important for today’s factories.

PETG is used a lot for packaging. By 2025, packaging will be almost half of all PETG use. You will see PETG in food, drink, medicine, and makeup containers. These containers must be safe, clear, and tough. PETG does all of this. Companies also make sheets, films, bottles, and shaped parts from PETG. This plastic works with both molding and extrusion machines.

Here is a table that lists main facts about PETG in industry:

| Aspect | Details |

|---|---|

| Major Applications | Packaging (45% market share in 2025), medical devices, signage, prototyping, 3D printing |

| Market Size Forecast | USD 2.94 billion in 2025 to USD 4.08 billion by 2035 |

| CAGR | 3.3% (2025-2035) |

| Leading Companies | Eastman Chemical Company, SK Chemicals, Celanese Corporation, Daicel Corporation, Clariant Ltd |

| Regional Growth | Asia-Pacific (strongest), North America, Europe |

| Growth Drivers | Healthcare, electronics, sustainable packaging, recyclability, bio-based PETG, advanced manufacturing |

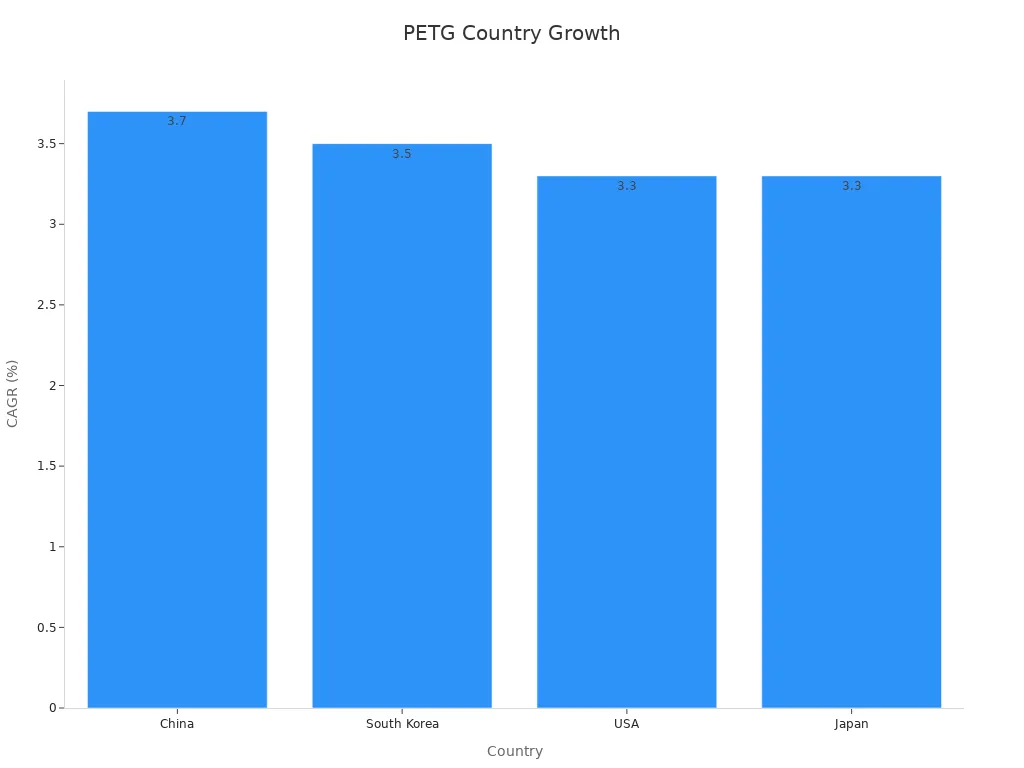

PETG is getting more popular every year. The market will grow from USD 2.94 billion in 2025 to USD 4.08 billion by 2035. The growth rate each year will be 3.3%. Asia-Pacific grows fastest, then North America and Europe. Countries like China, South Korea, the USA, and Japan are growing quickly.

Many companies make and sell PETG. Eastman Chemical Company has the biggest share. SK Chemicals and Celanese Corporation are also big names. These companies make PETG for things like sheets, bottles, films, and medical parts.

PETG helps new trends in factories. Many places want materials that can be recycled and are better for the planet. PETG can be recycled and comes in bio-based types. Sometimes, PETG is used instead of polycarbonate because it is easier and safer to use.

You can use PETG in 3d printing to make test parts and special items. This helps companies try new ideas fast. PETG’s strength and flexibility help make products that work well in real life.

Note: PETG is used in many ways and its market is growing, so it is a top pick for factories and industry.

Advantages

Easy Processing

PETG is simple to use in many places. You can shape, cut, or print it easily. It melts at a lower temperature than some plastics. You do not need special machines for PETG. You can use it for 3D printing or molding. Simple tools can cut PETG. It sticks well to print beds and does not warp much. This helps you get smooth and neat prints. Most 3D printers work with PETG. You do not need a heated chamber. Both beginners and experts like using PETG.

Tip: Clean your print bed and dry your PETG filament before printing for the best results.

Safety

PETG is safe for many important uses. You can use it for food packaging and medical things. PETG is clear and tough. It resists chemicals and stays strong over time. The FDA says PETG is safe for medical devices. This means it follows strict safety rules. You will see PETG in medical packaging and tools. It is also used for dental aligners. PETG is biocompatible, so it works with living tissue. This is good for medical implants and devices.

- You can sterilize PETG easily to keep things safe.

- Hospitals and clinics use PETG because it does not react with most chemicals.

- PETG has a strong safety record. Similar materials like PET have been used in medical implants since the 1960s.

You can trust PETG for products that must be safe and clean.

Versatility

PETG is one of the most useful plastics. You can find it in many industries. It is used in cars, electronics, and packaging. PETG comes in many thicknesses. You can pick thin sheets for packaging. Thicker sheets are good for signs and machine parts. The PETG market is growing fast. In 2023, it was worth USD 650 million. Experts think it will reach USD 1.12 billion by 2032. More people are picking PETG for many uses.

| Sector | Example Uses | Why PETG Works Well |

|---|---|---|

| Automotive | Lightweight parts | Durable, easy to shape |

| Electronics | Protective covers | Clear, strong, chemical resistant |

| Construction | Displays, panels | Tough, weather resistant |

| Packaging | Food trays, bottles | Safe, clear, easy to recycle |

| Cosmetics | Innovative packaging | Attractive, easy to mold |

PETG is good for recycling too. Mixing it with polystyrene makes it stronger and more flexible. PETG keeps its quality after being recycled many times. This makes it a smart choice for making things in a way that is better for the planet.

Note: PETG is so versatile that you can use it for almost any project, from simple models to big industrial parts.

Disadvantages

Oozing

When you print with PETG, you may notice oozing. Oozing happens when melted plastic leaks from the nozzle during 3D printing. This can leave thin strings or blobs on your finished part. You might see these strings between different sections of your print. Oozing can make your prints look messy or less accurate.

You can reduce oozing by adjusting your printer settings. Lowering the print temperature helps control the flow of PETG. Increasing retraction distance and speed can also pull the filament back into the nozzle, which stops leaks. Keeping your filament dry is important. Moisture in PETG can make oozing worse. Store your filament in a sealed container with desiccant to keep it dry.

Tip: Clean your printer nozzle often. A clean nozzle helps prevent extra plastic from sticking to your prints.

Brittleness

PETG gives you a good balance between strength and flexibility, but it can still show some brittleness in certain situations. If you print thin parts or use low infill, your objects may snap or crack under pressure. Sharp corners or thin walls can break more easily than thicker, rounded designs.

You can make your prints stronger by using higher infill settings and thicker walls. Rounded edges help spread out stress, so your parts last longer. If you need a part that bends a lot, try changing your design to avoid sharp angles. PETG works well for many uses, but you should plan your print for the best results.

Heat Limits

PETG stands out for its heat resistance compared to many other 3D printing plastics. You can use PETG for parts that face warm conditions, but it does have a clear upper limit. PETG keeps its shape and mechanical strength up to about 70°C. If you use PETG above this temperature, you may see your part start to soften or deform, especially if it holds weight or faces stress for a long time.

This heat limit means PETG works well for most indoor and light outdoor uses. It performs better than PLA, which starts to deform at 50–55°C. However, if you need a part for high-heat environments, you should look for a material with a higher temperature rating. PETG is not the best choice for parts near engines, ovens, or direct sunlight for long periods.

You should also think about recycling when you use PETG. PETG can be recycled, but you need to keep it separate from other plastics for the best results. Many recycling centers accept PETG, so you can help reduce waste by choosing this material. Always check local recycling guidelines to make sure your PETG parts are handled properly.

Recycling

Recycling PETG is not as easy as with some plastics. PETG is a thermoform plastic. It looks like PET but is different in some ways. You can find PETG in clear food boxes and trays. Many people want to recycle these items, but there are problems.

- PETG and other thermoforms often get mixed with other plastics. These include OPS, PLA, and PVC. This makes sorting at recycling centers hard.

- Labels and glue on PETG containers can cause trouble. Some labels use strong glue or paper that does not break down. These can mess up the recycling process.

- PETG containers are thin. When shredded, the flakes are light and fluffy. This makes washing and moving them harder during recycling.

- PETG has a lower intrinsic viscosity than PET bottles. Mixing them can lower the quality of recycled products.

Here is a table that shows recycling rates for different plastics:

| Plastic Type | Recycling Rate (2018) |

|---|---|

| PET bottles and jars | 29.1% |

| HDPE natural bottles | 29.3% |

| Overall plastics | 8.7% |

PET bottles are recycled more than most plastics. This means bottles are easier to collect and recycle. PETG thermoforms do not get recycled as much. Sorting and processing make it harder.

If you care about recycling, PETG can still be recycled. You should keep PETG apart from other plastics for best results. Some recycling centers take PETG, but check your local rules. Recycled PETG can become new boxes or containers.

Tip: Rinse and take off labels from PETG before recycling. This helps make better recycled products and supports good recycling.

You now know what PETG is and why it matters. PETG is a strong, clear plastic that you can use for 3D printing, packaging, and medical tools. You get easy processing, safety, and flexibility with this material. If you want reliable prints, keep your filament dry and use the right settings. PETG gives you a smart choice for projects that need strength and clarity.

Tip: Try PETG for your next project if you want a material that is tough, safe, and easy to use!

FAQ

What is PETG used for?

You can use PETG for 3D printing, food packaging, medical devices, and industrial parts. It works well for projects that need strength, clarity, and safety.

What makes PETG different from PLA?

PETG is tougher and more flexible than PLA. You can use PETG for parts that need to bend or handle impacts. PLA is easier to print but breaks more easily.

What does PETG stand for?

PETG stands for Polyethylene Terephthalate Glycol. The glycol makes the plastic easier to shape and less brittle than regular PET.

What are the main benefits of PETG?

You get high strength, good flexibility, and clear prints with PETG. It resists chemicals and heat better than many other plastics. PETG is also food-safe.

What print settings work best for PETG?

You should set your nozzle temperature between 230°C and 250°C. Use a heated bed at 70°C. Keep your filament dry for the best results.

What makes PETG food-safe?

PETG does not release harmful chemicals. The FDA approves it for food contact. You can use it for containers, trays, and bottles that touch food.