Polylactic Acid (PLA) is a biodegradable polymer that stands out for its eco-friendly nature. It is derived from renewable resources, such as corn starch or sugarcane. These materials provide the lactic acid monomers that form the backbone of PLA. Unlike traditional plastics, PLA offers a sustainable option that reduces environmental impact. You might wonder, what is PLA most valued for? Its ability to decompose naturally makes it an excellent alternative for reducing plastic waste.

Key Takeaways

-

PLA is a plastic that breaks down naturally. It is made from plants like corn and sugarcane, so it is better for the planet than regular plastics.

-

Making PLA creates much less pollution compared to normal plastics. This helps keep the air cleaner.

-

PLA can be used for many things, like food packaging, 3D printing, and medical tools. It is light and breaks down over time.

-

Using PLA helps the Earth because it rots naturally and cuts down on trash if thrown away the right way.

-

Knowing the difference between soft and hard PLA helps you pick the best one for your needs. This makes sure it works well.

Definition and Chemical Composition

PLA, or Polylactic Acid, is a biodegradable polymer made from lactic acid molecules. These molecules are derived from fermented plant materials, such as corn, sugarcane, and cassava. Chemically, PLA consists of the compound C3H4O2, which forms its structure. Unlike traditional plastics, which rely on petroleum-based materials, PLA uses renewable resources. This makes it a sustainable choice for various applications.

Here’s a quick look at its composition and sources:

|

Composition |

Source of Monomers |

|---|---|

|

C3H4O2 |

Corn |

|

|

Cassava |

|

|

Sugarcane |

|

|

Sugar beet pulp |

Sources of Raw Materials

The raw materials for PLA production come from plants rich in starch or sugar. Corn is the most common source, especially in North America. In regions like Southeast Asia, cassava serves as a significant alternative due to its high starch content. Sugarcane, widely grown in Brazil and India, provides renewable sugars essential for PLA production. Other sources include sugar beet and agricultural residues, which align with sustainability goals by utilizing waste materials.

|

Raw Material |

Description |

Region of Significance |

|---|---|---|

|

Corn |

Major source for PLA production, widely used in various regions. |

North America |

|

Cassava |

Significant in regions where corn is less prevalent; high starch content. |

Southeast Asia |

|

Sugarcane |

Provides renewable sugars; supports sustainable practices. |

Brazil, India |

|

Sugar Beet |

Another source of fermentable sugars for PLA production. |

Various regions |

|

Agricultural Residues |

Utilizes waste materials, aligning with sustainability principles. |

Global |

|

Non-edible Crops |

Offers alternative sources, reducing competition with food crops. |

Global |

Importance of PLA in Sustainability

PLA plays a crucial role in reducing environmental impacts. Traditional plastics release 2.4 metric tons of carbon dioxide per metric ton during production. In contrast, bioplastics like PLA produce only 0.828 metric tons. This significant reduction in greenhouse gas emissions makes PLA a more eco-friendly option. Additionally, the global warming potential (GWP) of PLA is much lower than other bioplastics. For instance, PLA has a GWP of 0.65 kgCO2e per kg, compared to 5.28 kgCO2e per kg for PHB. By choosing PLA, you contribute to a cleaner and more sustainable future.

How is PLA Made?

Production Process Overview

PLA production begins with renewable plant-based materials like corn, sugarcane, or cassava. These plants provide the sugars and starches needed to create lactic acid, the primary building block of PLA. The process involves converting these raw materials into lactic acid through fermentation. This lactic acid is then polymerized to form PLA, a biodegradable polymer.

The efficiency of PLA production depends on the availability of raw materials and the manufacturing process. For example, in Thailand, sugarcane plays a significant role in PLA production. With an annual sugarcane yield of 100 million tons, only 1.4% of the sugar produced is used for PLA manufacturing. This demonstrates how efficiently resources are utilized without significantly impacting food supply or land use.

-

Key Statistics:

-

Annual sugarcane production: 100,000,000 tons

-

Sugar yield per ton of sugarcane: 0.10473 tons

-

Land required for PLA production: 20,000 hectares (0.12% of Thailand's arable land)

-

Role of Fermentation in PLA Production

Fermentation is a critical step in producing high-quality PLA. During this process, microorganisms convert sugars from raw materials into lactic acid. Maintaining optimal conditions ensures maximum efficiency and yield.

|

Metric |

Value |

|---|---|

|

pH |

4.8–5.7 |

|

Hydraulic Retention Time |

2 days |

|

Temperature |

55ºC |

|

Bioaugmentation Strategy |

Improved lactic acid yield without reinoculation |

These parameters help achieve consistent lactic acid production, which directly impacts the quality of PLA. By optimizing fermentation, manufacturers can reduce waste and improve sustainability.

Key Steps in Manufacturing

The manufacturing process of PLA involves several key steps:

-

Fermentation: Microorganisms break down sugars into lactic acid.

-

Purification: The lactic acid is purified to remove impurities.

-

Polymerization: The purified lactic acid undergoes polymerization to form PLA.

-

Pelletization: The PLA is processed into pellets, which can be used for various applications.

Each step plays a vital role in ensuring the final product meets quality standards. By understanding these steps, you can appreciate the complexity and precision involved in creating PLA.

Properties and Applications of PLA

Key Properties of PLA

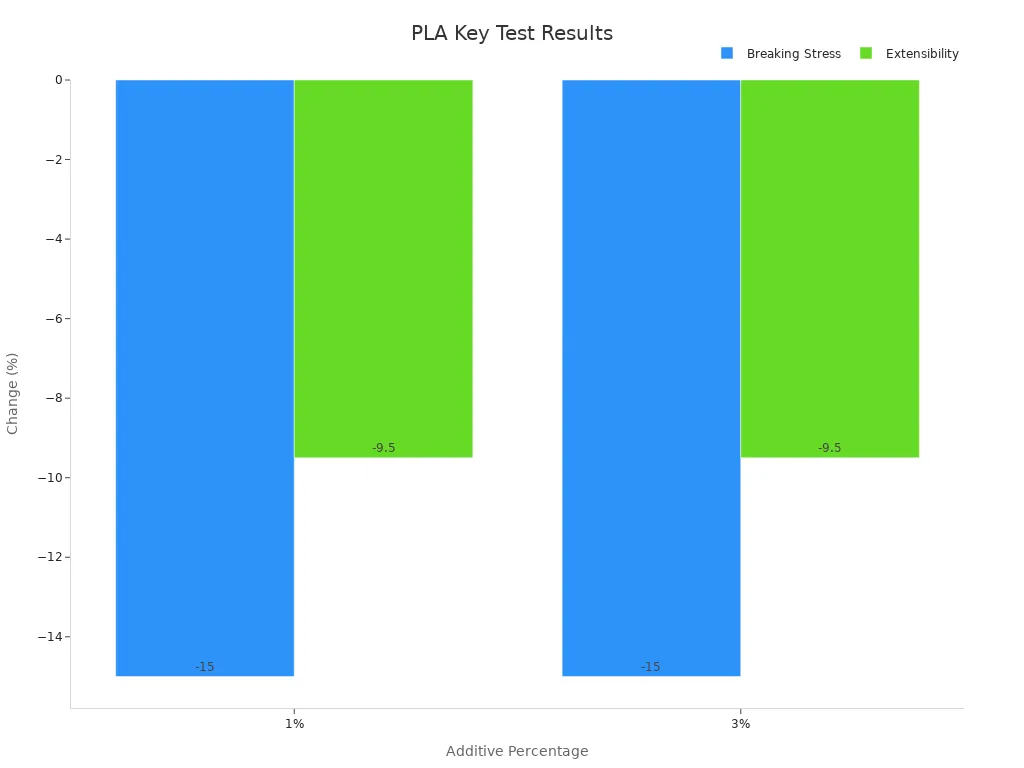

PLA exhibits several unique properties that make it a versatile material. It is lightweight, biodegradable, and has a low melting point, which simplifies processing. Its tensile strength is comparable to traditional plastics like PETG, making it suitable for various applications. Recent studies highlight its mechanical properties, such as breaking stress and extensibility, which vary based on additive percentages.

|

Property |

Additive Percentage |

Change (%) |

Statistical Significance |

|---|---|---|---|

|

Breaking Stress |

1% |

-15% |

Significant (α = 0.05) |

|

Breaking Stress |

3% |

-15% |

Significant (α = 0.05) |

|

Extensibility |

1% |

-9.5% |

Significant (α = 0.05) |

|

Extensibility |

3% |

-9.5% |

Significant (α = 0.05) |

|

Biodegradability |

3% |

Increased |

Significant (α = 0.05) |

|

Biodegradability |

5% |

Increased |

Significant (α = 0.05) |

PLA's biodegradability increases with higher additive percentages, making it an eco-friendly choice. Its ability to decompose naturally aligns with sustainability goals, reducing environmental impact.

Applications in Packaging and 3D Printing

You will often find PLA in packaging materials, such as food containers and disposable utensils. Its non-toxic nature makes it safe for food contact. Additionally, PLA's low melting point and ease of extrusion make it a favorite in 3D printing. It allows you to create intricate designs with minimal effort.

PLA's tensile properties also play a role in its popularity. A tensile test comparison between PLA and PETG revealed no significant differences in stress limits. This means PLA can perform similarly to traditional plastics in many applications.

|

Findings |

Description |

|---|---|

|

Tensile Test Results |

No significant differences between tensile stress limits of PETG and PLA specimens. |

|

Cluster Analysis |

Divided tensile test results into three groups based on stress values. |

|

Correlation Analysis |

Statistically significant correlation between filling percentage and tensile properties. |

|

Regression Models |

Showed relationships between filling percentage and secant modulus. |

Use in Medical and Industrial Fields

PLA's biocompatibility makes it ideal for medical applications. You can find it in sutures, implants, and drug delivery systems. Its ability to degrade safely within the body ensures minimal side effects. In industrial settings, PLA is used for creating prototypes and molds. Its versatility and eco-friendly nature make it a preferred choice for sustainable manufacturing.

Tip: When selecting PLA for medical or industrial use, consider its type—amorphous or crystalline—as each offers distinct advantages.

Advantages and Disadvantages of PLA

Benefits of PLA

PLA offers several advantages that make it a popular choice for sustainable materials. It is made from renewable resources like corn and sugarcane, which reduces dependence on fossil fuels. Its production generates a lower carbon footprint compared to traditional plastics. For example, manufacturing PLA emits significantly less greenhouse gas, helping you contribute to a cleaner environment.

PLA is also compostable under industrial conditions. This means it can break down into natural elements, reducing waste in landfills. Additionally, it emits fewer toxic fumes when incinerated, making it safer for disposal. Its low melting point makes it easy to process, especially in applications like 3D printing.

Did you know? PLA is one of the most widely used bioplastics in the world due to its versatility and eco-friendly properties.

Limitations and Challenges

Despite its benefits, PLA has some limitations. It is more expensive to produce than conventional plastics, which can increase costs for manufacturers and consumers. Since PLA relies on food crops like corn, it may compete with food production, potentially impacting agricultural resources.

PLA's material properties also present challenges. Its lower melting point makes it unsuitable for high-temperature applications. For instance, PLA containers may warp or deform when exposed to heat. Additionally, PLA has higher permeability, which can lead to faster spoilage of packaged goods.

|

Category |

Advantages |

Disadvantages |

|---|---|---|

|

Production |

Made from renewable resources, lower carbon footprint, produced in the USA |

More expensive than fossil-based plastics, uses food crops, potential negative agricultural impacts |

|

Material |

Lower melting point, easy to work with, popular in 3D printing |

Unsuitable for high-temperature applications, higher permeability leading to faster spoilage |

|

End-of-life |

Compostable, emits less toxic fumes when incinerated |

Slow composting, does not improve soil quality, not easily recyclable with other plastics |

Environmental Impact Compared to Plastics

PLA stands out as an eco-friendly alternative to traditional plastics. Its production emits fewer greenhouse gases, reducing its overall environmental footprint. Unlike petroleum-based plastics, PLA comes from renewable resources, which helps conserve non-renewable energy sources.

However, PLA's environmental benefits depend on proper disposal. While it is compostable, it requires industrial composting facilities to break down efficiently. Without access to these facilities, PLA may not degrade as quickly as expected. Recycling PLA also poses challenges since it cannot be mixed with other plastics.

By choosing PLA, you can support a shift toward sustainable materials. However, understanding its limitations ensures you make informed decisions about its use.

Types of PLA

Overview of Amorphous and Crystalline PLA

PLA exists in two primary forms: amorphous and crystalline. These forms differ in their molecular structure and physical properties. Amorphous PLA has a random molecular arrangement, making it transparent and flexible. Crystalline PLA, on the other hand, has an organized molecular structure, which gives it higher strength and thermal resistance.

The classification of PLA into these types depends on its crystallinity index. Studies show that adding 1 wt% cellulose nanocrystals (CNC) to PLA increases its crystallinity by 26%. This enhancement improves its thermal and mechanical performance, making crystalline PLA suitable for demanding applications.

Fun Fact: The degree of crystallinity in PLA affects its biodegradability. Higher crystallinity slows down decomposition, while amorphous PLA decomposes faster.

Characteristics of Each Type

Each type of PLA offers unique characteristics that suit different needs:

-

Amorphous PLA:

-

Transparent and glossy appearance.

-

Lower melting point, making it easier to process.

-

Suitable for applications like packaging and 3D printing.

-

-

Crystalline PLA:

-

Higher tensile strength and thermal resistance.

-

Opaque and rigid structure.

-

Ideal for medical implants and industrial uses.

-

Mechanical testing reveals that crystalline PLA reinforced with CNC achieves a tensile strength of 48.9 MPa, which is 35.5% higher than pure PLA. This makes it a strong contender for high-performance applications.

Choosing the Right Type for Applications

Selecting the right PLA type depends on your specific requirements. For example:

-

Use amorphous PLA for products requiring flexibility and transparency, such as food containers or 3D printing filaments.

-

Opt for crystalline PLA when durability and heat resistance are critical, such as in medical devices or automotive parts.

Metrics like tensile strength, thermal stability, and biodegradability help you decide. For instance, crystalline PLA performs better in high-temperature environments, while amorphous PLA excels in applications needing faster decomposition.

Tip: Always consider the end-use environment and performance demands when choosing between amorphous and crystalline PLA.

PLA represents a biodegradable polymer derived from renewable resources like corn and sugarcane. Its composition, based on lactic acid monomers, makes it a sustainable alternative to traditional plastics. You can rely on PLA for its lightweight, biodegradable nature and versatility in applications like packaging, 3D printing, and medical devices.

PLA also promotes sustainability and innovation. Studies show high consumer satisfaction (M = 4.5) with sustainable practices, while strong relationships (R² = 0.79) exist between these practices and business performance. By choosing PLA, you support eco-friendly solutions that reduce waste and drive progress in multiple industries.

FAQ

What makes PLA different from traditional plastics?

PLA comes from renewable resources like corn and sugarcane, unlike traditional plastics made from petroleum. It decomposes naturally under industrial composting conditions, reducing waste and environmental harm.

Can you recycle PLA?

Yes, but PLA recycling requires specialized facilities. It cannot mix with other plastics due to its unique composition. Check local recycling guidelines to ensure proper disposal.

Is PLA safe for food packaging?

PLA is non-toxic and safe for food contact. It’s commonly used for disposable utensils, containers, and wraps. Its biodegradable nature makes it an eco-friendly choice for food packaging.

Does PLA work for high-temperature applications?

No, PLA has a low melting point. It may warp or deform under high heat. For heat-resistant applications, consider alternatives like crystalline PLA or other bioplastics.

How long does PLA take to decompose?

PLA decomposes within 3-6 months in industrial composting facilities. In natural environments, decomposition takes longer due to less favorable conditions.