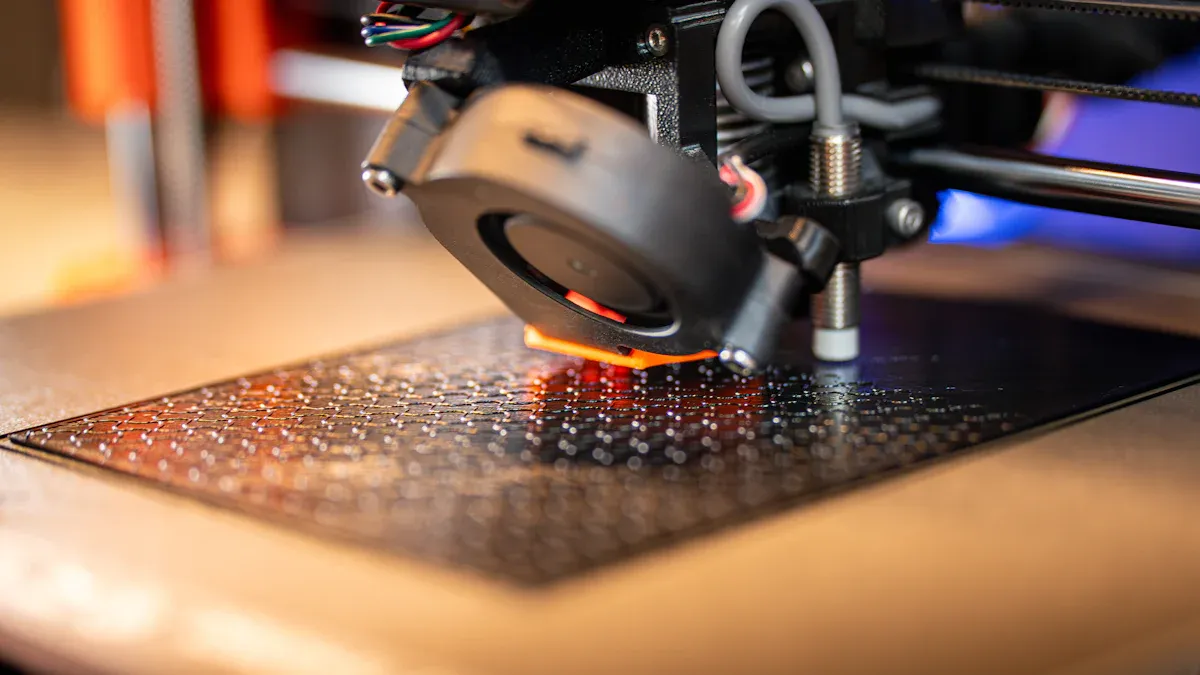

Thermoplastic polyurethane (TPU) is revolutionizing 3D printing with its unique properties. But what is TPU material? It is a versatile substance known for its flexibility, durability, and resistance to chemicals, making it invaluable across various industries. By 2025, the 3D printing market is projected to expand from $1.05 billion to $2.58 billion, reflecting an impressive annual growth rate of 19.64%. Both the healthcare and automotive sectors are leveraging TPU material to drive innovation, with a strong emphasis on eco-friendly and reusable solutions.

In healthcare, TPU material is utilized for creating medical tubes and bandages, while automakers incorporate it into lighter vehicle components to enhance fuel efficiency. These advancements highlight how TPU material addresses numerous challenges across industries.

Key Takeaways

-

TPU is a useful material. It is stretchy like rubber but strong like plastic. This makes it great for many 3D printing uses.

-

By 2025, 3D printing will grow a lot. TPU will be important in areas like healthcare and cars because it is better for the environment.

-

New TPU filaments and printing methods help make detailed, bendable designs. This allows for new products and greener ways to make things.

What is TPU Material and Why Does it Matter?

What is Thermoplastic Polyurethane (TPU)?

TPU is a material that acts like both rubber and plastic. It can stretch like rubber but is strong like plastic. Its structure has hard and soft parts, which can be changed to make it more flexible or stiff. This makes TPU useful for many things, like car parts and medical tools. TPU is tougher than materials like PVC or rubber. It doesn’t wear out easily and can handle oil, chemicals, and germs, lasting longer in tough conditions.

Why is TPU Great for 3D Printing?

TPU has special qualities that make it great for 3D printing. It can handle stress and bending without breaking. Its softness helps it stick well to other materials, making it good for mixing materials in one product. TPU also allows for creating detailed shapes that are hard to make with regular methods. Most people use FDM printers for TPU because it’s cheap and easy to use.

Pros and Cons of TPU in 3D Printing

TPU has many benefits in 3D printing. It is flexible, safe for the body, and sticks well to other materials. For example, TPU can handle being pulled with a force of 1 kg without breaking. But it does have some downsides. Printing very detailed or big designs with TPU can be tricky using FDM printers. Even with these issues, TPU is still a top choice for projects needing strength and flexibility.

Applications of TPU in 3D Printing

Prototyping and Product Development

TPU is important for making prototypes and new products. Its flexibility and strength help create models that act like real items. This is great for testing how designs handle stress or wear. TPU can make detailed shapes that regular methods cannot. It also allows mixing soft and hard parts in one design. This saves time and money during development.

Wearable Technology and Fashion

TPU is growing in wearable tech and fashion use. It helps make light, flexible, and strong parts for fitness bands and smart clothes. 3D printing now makes custom designs with complex shapes possible. TPU is great for comfy, body-fitting wearables. In fashion, TPU creates unique, eco-friendly designs that look good and work well.

Automotive and Aerospace Applications

TPU is changing cars and planes.

-

It improves safety, comfort, and durability in vehicles.

-

Car makers use TPU for lighter parts, saving fuel and helping electric cars.

-

Plane engineers use TPU for parts that handle tough conditions.

These uses show TPU is better than older materials for advanced designs.

Medical and Healthcare Innovations

TPU is very useful in healthcare. It is safe and strong for medical tools like catheters and stents. TPU is also used in tubes and bandages, keeping patients safe and comfy. More PPE made from TPU is needed for clean healthcare spaces. TPU also helps make custom prosthetics that fit better and feel good. These uses are changing healthcare for the better.

Sustainability and TPU in 3D Printing

Eco-Friendly Manufacturing with TPU

TPU is helping make manufacturing more eco-friendly. 3D printing with TPU creates only the needed parts, reducing waste. Unlike older methods, it doesn’t cut away extra material. This saves energy and lowers pollution.

Companies are finding new ways to make TPU greener. For example:

-

Some use farm waste to make TPU, cutting fossil fuel use.

-

Others turn CO2 into TPU materials, using harmful gases for good.

-

Recycling systems reuse old TPU, reducing waste even more.

These methods show TPU’s role in green manufacturing’s future.

Recycling and Reusability of TPU Materials

TPU is great because it can be reused many times. Materials like Ultrasint® TPU keep 80% of their strength after recycling. This means TPU can be recycled without losing quality.

Startups like HILOS use TPU to make eco-friendly items like shoes. They show how recycled TPU can become new products without much wear. Studies prove TPU stays strong even after being recycled several times. This makes it perfect for industries wanting less waste and more sustainability.

Energy-Efficient Printing Techniques for TPU

TPU’s strength and flexibility make it great for saving energy in printing. Research shows TPU stores energy well, making it useful for prosthetics. For instance, TPU can store 0.044 J/Kg of energy, better than carbon fiber.

Using TPU allows for detailed designs with less energy. This saves resources and supports eco-friendly goals. TPU’s special features make it a top choice for green manufacturing.

Emerging Technologies and TPU's Role in 2025

Flexible Electronics and Smart Devices

TPU is changing flexible electronics and smart gadgets. Its stretchiness and strength make it great for advanced wearables. Scientists made 3D thermoelectric fabrics using TPU. These fabrics collect energy and sense changes, helping with human-machine interaction.

TPU is key in wearable thermoelectric devices (F-TEDs). These devices gather energy and track health in real time. TPU-based electronics are light and flexible, improving healthcare and gadgets. For example:

-

Flexible electronics help with health tracking and biosensing.

-

TPU makes wearables more comfy and useful.

-

Smart gadgets with TPU save energy and work better.

Integration with AI and IoT in Manufacturing

TPU helps connect AI and IoT in factories. TPU-based AI chips process data quickly in smart devices. This lowers delays and helps devices make decisions on their own. For example, TPU chips predict machine problems, keeping factories running smoothly.

In edge computing, TPU chips handle data nearby, not in data centers. This makes things like video calls faster. Google’s TPU shows how AI can improve chip performance for learning tasks. Combining TPU with AI and IoT makes factories smarter and greener.

Composite Materials and Enhanced Thermal Stability

TPU is helping create stronger materials that handle heat better. These materials mix TPU with others to survive extreme temperatures. In cars and planes, TPU composites boost safety and performance.

TPU’s growth in industries shows its value. Here’s a summary:

|

Sector |

|

|---|---|

|

Cars and Transport |

Big increase |

|

Buildings |

Steady rise |

|

Planes |

Important role |

|

Energy |

More expansion |

By 2025, TPU will keep growing in composites. It will offer new solutions for tough and heat-resistant products.

Trends for TPU Material in 3D Printing for 2025

Innovations in TPU Filaments and Printing Techniques

TPU filaments are changing how 3D printing works. These filaments mix hard and soft parts, making them stretchy like rubber but easy to shape like plastic. This helps create flexible items like cushions, medical supports, and soft robots. New improvements make printing smoother by fixing how filaments pull back and cool down. These changes stop bending during printing, making parts more accurate. TPU can also melt and be reused without losing its strength, which helps reduce waste.

Now, TPU filaments can make more detailed designs. Flexible electronics and airless tires use TPU because it bends and stays strong. Scientists are working to make TPU filaments even better, so they can be used for more things in 3D printing.

Increased Adoption Across Consumer and Industrial Markets

TPU is being used in many industries because it’s so useful. Car makers use TPU to make lighter parts that save fuel. In healthcare, TPU helps make custom medical tools and new ways to print body-safe items. Companies making everyday products like shoes and sports gear also use TPU because it lasts long and bends easily.

Studies show factories use TPU the most, making up 70% of its market. Healthcare comes next with 20%, as it needs safe materials for people. Asia-Pacific is growing fast in TPU use because of more factories, while North America and Europe still use TPU a lot. This shows TPU is becoming more important in 3D printing everywhere.

Focus on Biodegradable and Sustainable TPU Materials

Making TPU eco-friendly is a big focus now. Some companies are creating TPU that breaks down naturally. For example, Algenesis made a TPU that can decompose in home compost bins. Tiny organisms in soil turn this TPU into nutrients and gas, helping the environment by reducing plastic waste.

Recycling TPU is also becoming popular. TPU stays strong even after being reused, making it a smart choice for cutting waste. By 2025, biodegradable TPU and recycling will be key in 3D printing, helping the planet and meeting global green goals.

TPU is changing 3D printing with its strength and flexibility. It helps cut waste and supports green manufacturing methods. TPU is also important in new tech, like smart gadgets and AI systems. By 2025, TPU will improve industries and solve big problems worldwide.

FAQ

How is TPU different from other 3D printing materials?

TPU is special because it bends and lasts long. It’s great for making parts that need to flex or handle pressure without breaking.

Can all 3D printers use TPU?

No, not every printer works with TPU. You need a printer with a direct drive extruder and settings that can adjust for its softness.

Is TPU okay for medical use?

Yes, TPU is safe for medical tools like prosthetics and bandages. It’s strong and flexible, which helps keep patients comfortable and safe.