After released our New Printer-STAR ONE,some of customers have not good feedback for it.They think this is the clone for Ender,we think most of printers are clones,because of similar appearance.We focus on inner part research and development,we improve the motherboard.Ok,Let see below article of Star one test from Nozzler.fr. Author:Gauthier Le Rouzic

Eryone Star One review

Hello everyone. I find you today for the testing of the latest filament 3D printer released from ERYONE: Star One FDM Printer.

First of all, a little presentation of the brand for those who don't know it. Then we will continue with the unboxing, and finally the printing tests before concluding.

The Introduce Of Eryone:

“Built on June 1, 2018, Shenzhen Eryone Technology Co., Ltd specializes in 3D printer research and development, manufacturing and domestic and international sales. Eryone focuses on the development of its own brand, its own R&D, committed to the path of internationalization. Eryone has a strong scientific manpower, maintaining close relationship with many prestigious universities in the field of scientific research and cooperation in China, (eg HUST. Wu Han University of Technology, Shen Zhen University , GuiZhou University, Etc…) to provide advanced scientific research products to the market. Eryone has strong market development capability, as well as operational capability and marketing capability in all kinds of e-commerce channels. In addition, Eryone has a strong supply chain, experience working with factories, deep knowledge of Chinese manufacturing industry, and at the same time rich resources from the outside company.

Unboxing & Build :

As you can see in the video above, the printer is relatively easy to assemble. Nothing too complicated and the assembly instructions are clear.

The characteristics of the Star One:

- Print volume 220 x 220 x 250mm

- Max nozzle temperature: 250°C

- Maximum bed temperature: 100°C

- Print resume function

- End of filament detector

- Print speed: Maximum 180mm/s, recommended: 30-60mm/s

- X and Y axis belt tensioner

- A basic MK8 hotend, with a sock

- Quiet drivers on all motors! 0 movement noise, very positive! They are MS35775, not common on a 3D printer, but they work great! Data Sheet to follow

- A super solid base, made with 4040 aluminum profiles like on the Lotmax SC-10 Shark V2 that I was able to test

- A 32-bit Cortex M4 motherboard with an HC32F460

Driver MS35775 DATASHEET

FEATURES AND BENEFITS

2-Phase stepping motor, can reach the peak current of 2A

Step / dir interface, you can choose 2, 4, 8, 16, or 32 micro step

Internal 256 micro steps

Quiet mode

Fast mode

HS Rdson 0.29 Ω ,LS Rdson 0.28 Ω

The voltage range is 4.75 ~ 36V

When the motor is still, it will enter into the power saving mode automatically

Internal resistor mode is optional (no need for external sense resistor)

Single wire UART bus and OTP control QFN28 package (Back Thermal PAD)

Lien : http://www.relmon.com/en/index.php/list/detail/231.html

We will immediately note a few negative points:

- no auto leveling (even if I'm not a fan, it has almost become a must-have option)

- no touch screen, a good old selection wheel

- Plastic MK8 extruder. Although I had no problems with it, and it seems much sturdier than some I've come across, a metal extruder would have been preferred.

- no double Z

- A hotend fan that is too noisy! it's a shame because it's really a silent printer, the noise of the fan ruins everything!

|

|

|

|

|

|

|

|

The Eryone Star One reviews:

First, I printed all the files on the micro SD card supplied with the machine. Here are the results :

So we have very well printed test files: a wheel to put on the axis of the extruder (perfect), a kind of hook (I have absolutely no idea what it's for, so if someone wants to enlighten my lantern…) and finally a double tool box, to slide into the 4040 uprights of the machine.

Everything is very well done. This little machine is starting to surprised me!

The double storage box allowed me to test end of filament detection and print resumption. The management is perfect, no difficulty at this level.

We feel that Eryone develops its own motherboards (hence the use of unusual drivers).

The profiles have been thoroughly optimized. Now we will have to see what the prints look like with our profile!

Surprise on this side, no profile is available either in the microSD card or on Cura, and I advise you not to put the profile of the ER20! So we will have to manage.

For an experienced maker, this step will not pose any problem, but I can conceive that for a newcomer to the world of 3D printing, it can be somewhat confusing.

For my part, I made the rest of the prints with SuperSlicer. And for once nothing very complicated. Enter the print volume: 220x220x250. Add a printer, select "Custom", check "Bowden 1.75mm nozzle 0.4mm", then "Finish". Then continue setting up the profile.

Or if can't, you can import my config to go faster:LINK

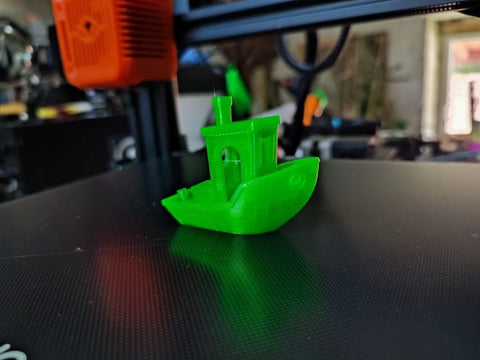

The benchy of families. Perfectly done. For a basic profile it's great.

The packer that allows me to check both the material ventilation and the structural solidity of the machine. For once it's straight and it doesn't move! Link to file. This file also allows you to work on your first layer.

An opinel handle, printed in layers of 0.2, and in PLA, I use it every day, for the moment it holds.

For information on this type of print, one could imagine printing it vertically to avoid supports. But it would weaken the handle given the direction of the layers. By printing horizontally, continuity of the contour lines is ensured over the entire length of the handle.

On the right the print made with the Eryone Star One.

And finally, to finalize the tests, the impression of a Miele vacuum cleaner handle that you can find here:LINK

Something to make your vacuum cleaner a little fun. FYI, this print is made in PLA, 100% filling.

Conclusion :

So on paper, the Eryone Star One does not necessarily make you dream, I grant you that. It lacks a few options that today have almost become essential (Auto leveling, color touch screen, wifi?). Personally, I am not for the multitude of options. This printer is therefore simple, but well thought out. Its architecture is reinforced by the use of 4040 throughout the base, it is solid and it will not move! The motherboard has been really well developed, the drivers are velvet! I think it's the quietest printer I've ever had... apart from the hotend fan, which really breaks the silence. The price on their site around 230€. Suddenly I no longer understand people who want to buy an Ender 3 at 190€… Come and test this one.

Test carried out by Gauthier Le Rouzic for Nozzler.fr